THE NEXT CENTURY IN ARTIFICIAL LIFT

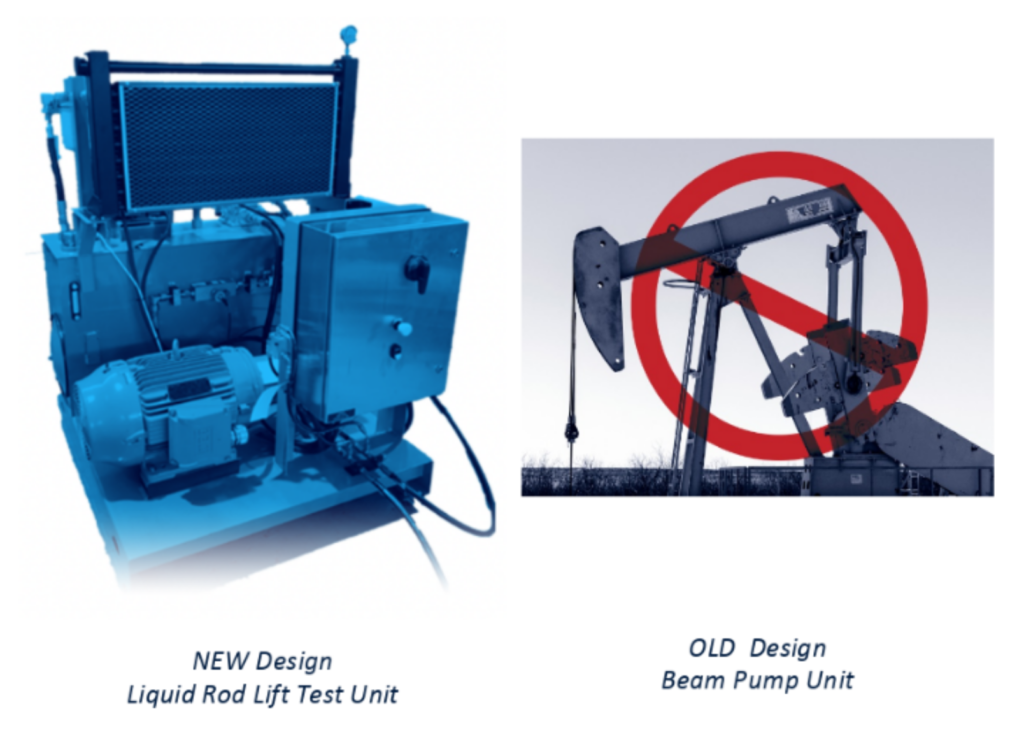

As oil fields mature and production declines, Operators frequently turn to traditional beam pumping as their ‘go-to’ form of artificial lift. However, beam pumping is a 100-year-old technology that has not changed much and was not designed to work in deviated or horizontal wellbores. The result of using Beam Pumps can lead to:

- high maintenance cost

- frequent rod and tubing failures

- high operating cost

- HSE issues with rebalancing these bulky units in the field

- lowering cost

- eliminating rod and tubing failures

- a clean and efficient system

- remote monitoring and control

- Operators can manage assets with confidence and deliver more profit from the well.

Introducing Liquid Rod™ Lift

Liquid Rod™ Lift is a new and patented artificial lift solution for modern wells with aggressive vertical trajectories and horizontal laterals.

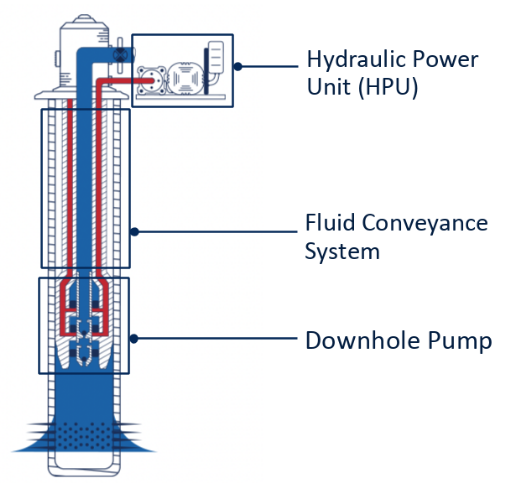

Contrary to traditional methods, the Liquid Rod Lift System does not utilize sucker rods or mechanical drive to power the downhole pump.

The system uses a closed-loop hydraulic pressure conduit to power the downhole pump. This allows the surface Hydraulic Power Unit to have a much smaller physical footprint than traditional Beam Pumps and it requires much less power to operate. The concept of the Liquid Rod™ Lift system is based on the operating principles of a U-Tube. Using two, near-balanced hydrostatic columns of fluid, the surface system drives the power fluid to cause the downhole pump to produce, then reset and refill. The system is highly efficient and does not lose energy through the friction of mechanical rods rubbing against the tubing string. You also do not have to waste energy lifting the weight of a rod string just to get a few gallons of fluid to the surface.Eliminates Rod and Tubing Failures

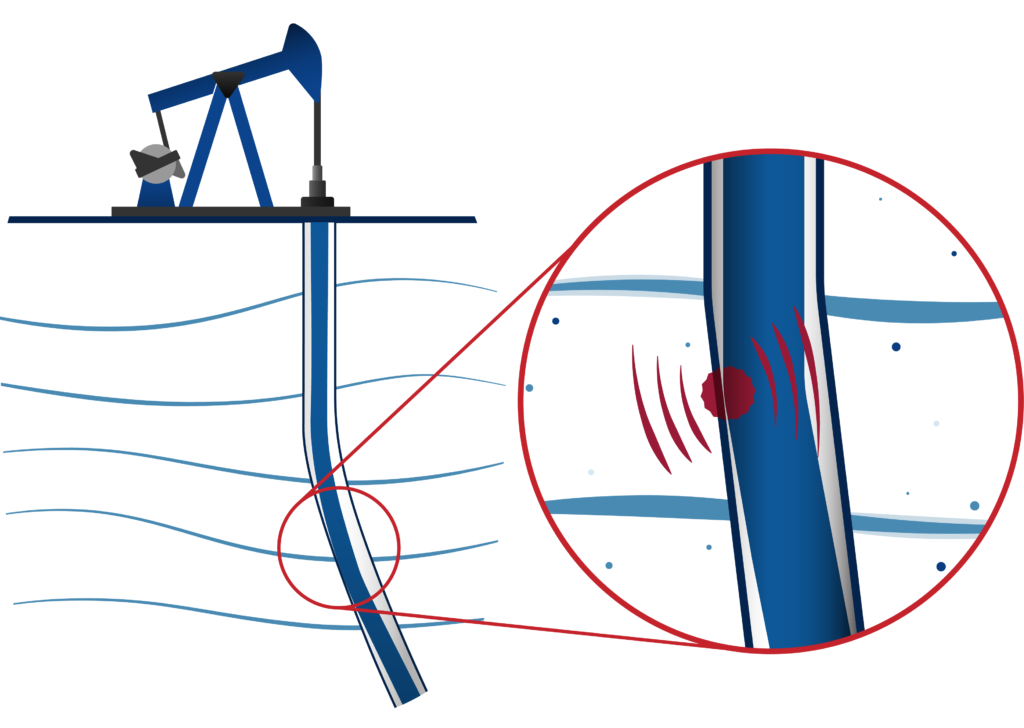

Because Liquid Rod™ Lift utilizes hydraulics to actuate the downhole pump system, the need to drill a perfectly straight well to accommodate lower rod friction and other moving equipment is greatly reduced. This allows the driller to drill faster wells, saving rig cost for the Operator.

The hydraulic drive system of Liquid Rod™ Lift allows for the elimination of all rods and rod guides typically used in conventional rod lift technology. There is no need for any reciprocation or rotation of mechanical rods inside the tubing string, thus eliminating all mechanical friction against the tubing string which frequently results in rod failures or wearing holes in the tubing string.

Many Operators have existing wells where their Beam Pumps are down several times per year which results in NPT and lost revenues. These types of wells are prime candidates for the Liquid Rod™ Lift System.

“The Value Proposition” Liquid Rod™ Lift -vs- Conventional Rod Lift (Beam Pumping)

CAPEX & OPEX

- Lower Capital Cost

- 30%-75% Less Power Consumption

- Lower Maintenance Cost

- Less Down Time

PRODUCTION VALUE

- Multi-Well Pad Applications

- Gas De-watering Applications

- Production Enhancement

- Horizontal Pump Placement

HSE

- Safer to Manage

- Fewer Maintenance Intervals

- Small Environmental Footprint

- Low Noise and Visual Impact

Liquid Rod™ Lift

Liquid Rod™ Lift Is a privately held company that is focused on the development and delivery of new technology to the artificial lift industry with the goal of providing safer and more efficient operations while enhancing the production value for our clients.

Our principle offices are in Houston, Texas with a dedicated team of highly qualified engineers and technicians devoted to developing the system for full commercialization in 2021.

After completing field proof-of-concept testing on several oil wells in the Permian Basin, we have finalized the full engineering design and analysis and are now seeking interested Production Engineers / Operators to conduct Field Trials on existing wells which have some history with beam pumping.

We will deliver much-improved value to the Operator through the benefits of the Liquid Rod™ Lift technology. Please contact us for more information.